Reverse Engineering

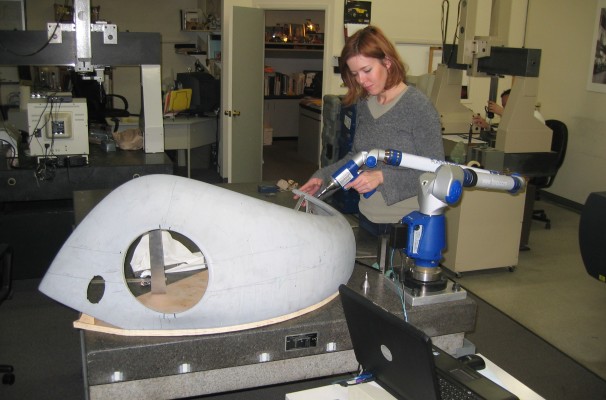

This fender was part of a larger project in which the entire VW Bug is to be reproduced at 1.5 scale. This will be the biggest VW Bug in the world, just small enough to fit in a normal lane and fully street legal. This photo shows Melinda collecting 3-D points using the Faro Arm. Following this scanning process, she generated a complete 3-D model of this part in the CAD system that was scaled up by 1.5.

Geoform has a large selection of digitizing tools and software for reverse engineering projects, including measurement tools from Zeiss, Faro, API and software from Polyworks, Metrolog, VX, Faro. We specialize in reverse engineering projects involving precision scanning of existing parts to produce clean 3-D CAD models suitable for CNC programming or 3-D printing. Our experience in manufacturing allows us to build CAD models targeted to a specific manufacturing process. For example, when we model a sand casting, we will include the appropriate draft, parting lines and cores necessary to make the part. Even in cases where these details cannot be scanned because they are machined away or worn, we will provide a clean complete model. We have extensive experience in tooling design, including sand casting, investment casting, metal forming (drop hammer, hydroform, mechanical press). As part of our reverse engineering services, we can design the tooling required to produce the parts using these manufacturing processes.