We used AutoCAD and Cadkey in the late 1980’s and migrated to Varimetrix advanced 3-D surfacing and solid modeling in 1991, when the technology was very new. We incorporated these technologies into our service offerings early on, realizing this would be the future of the industry. This made us the first inspection/reverse engineering lab on the West Coast to provide advanced surface and solid modeling.

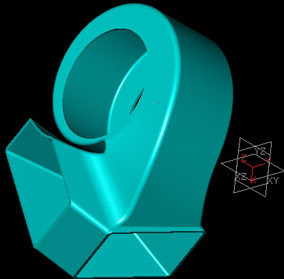

We specialize in reverse engineering projects involving precision scanning of existing parts to produce clean 3-D CAD models suitable for CNC programming or 3-D printing. Our experience in manufacturing allows us to build CAD models that are targeted to a specific manufacturing process. For example, when we model a sand casting, we will include the appropriate draft, parting lines and cores necessary to make the part. Even in cases where these details cannot be scanned because they are machined away or worn, we will provide a clean complete model.

We also specialize in the conversion of legacy data to 3-D geometry. We can translate your printed contour dataset or loft-line mylar to 3-D for use in tooling design, machining and inspection programming. Our high-end OCR software will accurately convert tabulated contour data or image files (including.C4 format) to numerical tables that can be imported into CAD programs. Our CAD engineers have years of experience in advanced 3-D surface modeling, with proven processes for ensuring accuracy between legacy data and finished 3-D geometry. Past projects include the entire body of the U.S. Army MQM-107 target drone and numerous fairing and airfoil surfaces for military and commercial aircraft.